Needles Anatomy

- Donna @ Miss Lavenders

- Jan 19, 2020

- 4 min read

Updated: Oct 24, 2020

We found this article on one of our suppliers sites EQS.

Are you on point with your needle knowledge?

Often, we have issues when sewing that we need to diagnose. Whether it be thread breaking or shedding, skipped stitches or needles snapping, it is regularly your needle that is the problem.

The needle is the first point of contact between the machine and your project, so you should never compromise on the quality of your needle.

There are lots of different types of machine needles, all designed for a different application or fabric.

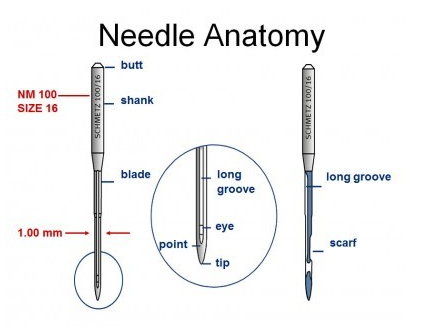

Needle Anatomy

First let’s talk about the anatomy of the machine needle as this helps to understand the differentiating factors of different needle types.

Butt The very top of your needle has a bevelled edge for easier insertion into your machine.

Shank The shank is the part that inserts into your sewing machine. Home sewing machine needles have a flat shank for perfect positioning in the needle bar.

Shoulder The transitioning area between the shank and the blade. Brands such as Schmetz add colour coding here to help you identify your needle.

Blade The length of the needle. Needle size is determined by measuring the bade width.

Groove Along the needle blade the groove cradles and guides thread to the eye of the needle.

Scarf The indentation above the eye that allows the bobbin hook to smoothly grab the thread under the throat plate to create a stitch.

Eye The hole through which thread passes.

Point and Tip The first area to penetrate fabric in stitch creation. The point and tip length, shape and size vary according to needle types.

Needle Life

A regular sewing machine needle should be replaced after eight hours of sewing time. If you don’t count your hours, then use the principle of a new needle for each new project.

If you have a stitching problem you should change your needle, as your needle is responsible for 45% of stitching problems.

Needle Sizing

American needle sizes range from 8 to 19, and European sizes range from 60 to 120. The larger the number, the larger the blade of the needle. Often, you'll see both sizing numbers on the needle package, like 60/8 and 70/10.

The needle size is calculated by the needle diameter. For example, a 90 needle is 0.9mm in diameter.

The finer the fabric the finer the needle needs to be. Here’s a quick guide. 60/8 Silk 70/10 Lightweight fabrics 75/11 Mediumweight fabrics 80/12 Mediumweight fabrics 90/14 Medium to heavyweight fabrics 100/16 Heavyweight fabrics 120/20 Denim

Needle Types

As needle technology has advanced needle manufacturers produce specific needles for specific applications and there are more and more as machines become more technical.

Universal Needles The Universal Needle has a slightly rounded point and is suitable for trouble-free sewing of most materials.

Embroidery Needle

The Embroidery Needle is designed for machine embroidery. It has a large eye for thicker threads, special effect or metallic embroidery threads. The larger eye also has a protective effect on the thread resulting in less thread breakage.

This needle has a larger cross-section of the groove to ensure gentle thread passage through eye and groove. The special construction of the transition from the eye to the scarf reduces the risk of skip stitches.

Embroidery needles have a small ballpoint which avoids damage to the (already embroidered) embroidery thread and the fabric.

Metallic Needles The Metallic needle is developed specially for metal effect thread, with very long eye (2 mm in all needle sizes) in relation to the needle thickness. The eye is even longer than in needle system 130/705 H-E (for embroidering) and remains the same in all needle sizes. The longer eye and the special groove allows the thread to glide easily and gently through the needle (and therefore prevent thread breakage). Tip: Slow down sewing speed when using metallic threads.

Topstitch Needles The Topstitch Needle has a longer eye and the special groove to offer space for thicker topstitching threads or for the use of two all-purpose sewing threads. These needles can also be used for machine embroidery or free motion embroidery in problematic materials.

Microtex Needles The Microtex needle has a very slim, acute point for easier piercing of very fine or densely woven fabrics. The stitch hole is smaller and seam puckering is reduced. This needle achieves precise and straight stitches (e. g. topstitching of edges) due to the point shape.

Jeans Needles The Jeans Needle has a slim, acute point for easier penetration of thick fabrics and a reinforced blade, which causes less deflection of the needle. The special shape of the scarf reduces the risk of skipped stitches. This needle is ideal for jeans (denim) and similar solid fabrics, workwear, artificial leather, waxed cloth and vinyl.

Quilting Needles The Quilting Needle has a slim, acute point, which is slightly rounded in order to penetrate thick layers of material easier during quilting by machine. This needle achieves accurate seams in quilting where many seams frequently cross each other and avoids damage in sensitive and often expensive materials used in patchwork.

Twin and Triple Needles The properties of these needles are equivalent to the respective single needles and used for pintucks, single and multicoloured seams and hems.

Thanks for EQS for this article

Wow. Learned more in 10 minutes than i have over last 2 minths of projects